Muna amfani da kukis don inganta ƙwarewar ku.Ta ci gaba da bincika wannan rukunin yanar gizon, kun yarda da amfani da kukis.Ƙarin Bayani.

Muna amfani da kukis don inganta ƙwarewar ku.Ta ci gaba da bincika wannan rukunin yanar gizon, kun yarda da amfani da kukis.Ƙarin Bayani.

Ƙarfafa masana'anta (AM) ya ƙunshi ƙirƙirar abubuwa masu girma uku, Layer mai kauri ɗaya a lokaci guda, yana mai da shi tsada fiye da injinan gargajiya.Duk da haka, kawai karamin sashi na foda da aka ajiye a yayin aikin taro ana sayar da shi a cikin sashin.Saura kuma baya narke, don haka ana iya sake amfani dashi.Sabanin haka, idan an ƙirƙiri abin na al'ada, ana buƙatar cire kayan ta hanyar niƙa da injina.

Halayen foda sun ƙayyade sigogi na injin kuma dole ne a fara la'akari da su.Farashin AM zai kasance maras tsada idan aka ba da cewa foda da ba a narkewa ba ta gurɓace kuma ba za a iya sake yin amfani da ita ba.Lalacewa ga foda yana haifar da abubuwa biyu: gyare-gyaren sinadarai na samfurin da canje-canje a cikin kayan aikin injiniya kamar ilimin halittar jiki da rarraba girman barbashi.

A cikin akwati na farko, babban aikin shine ƙirƙirar ƙwararrun sifofi waɗanda ke ɗauke da tsattsauran allo, don haka muna buƙatar guje wa gurɓataccen foda, alal misali, tare da oxides ko nitrides.A cikin akwati na ƙarshe, waɗannan sigogi suna haɗuwa da ruwa da kuma yadawa.Sabili da haka, duk wani canji a cikin kaddarorin foda na iya haifar da rarrabawar samfuran da ba ta dace ba.

Bayanai daga wallafe-wallafen kwanan nan sun nuna cewa na'urorin motsa jiki na gargajiya ba za su iya samar da isasshen bayani game da foda ba a cikin samar da kayan gado na foda.Game da halayen albarkatun kasa (ko foda), akwai hanyoyin auna da yawa da suka dace akan kasuwa waɗanda zasu iya gamsar da wannan buƙatu.Yanayin damuwa da filin kwararar foda dole ne su kasance iri ɗaya a cikin tantanin halitta da kuma a cikin tsari.Kasancewar nauyin matsawa bai dace ba tare da kwararar sararin samaniya kyauta da ake amfani da ita a cikin na'urorin AM a cikin masu gwajin ƙwayoyin shear da na gargajiya na rheometer.

GranuTools ya haɓaka ayyukan aiki don ƙididdige foda a masana'anta ƙari.Babban burinmu shine samun kayan aiki guda ɗaya akan kowane nau'in lissafi don ingantaccen ƙirar tsari, kuma an yi amfani da wannan aikin don fahimta da bin diddigin haɓakar ingancin foda a kan fassarori da yawa.An zaɓi madaidaitan allunan aluminum (AlSi10Mg) don lokuta daban-daban a nau'ikan zafi daban-daban (daga 100 zuwa 200 ° C).

Ana iya sarrafa lalatawar thermal ta hanyar nazarin ikon foda don adana caji.An bincika foda don gudana (kayan GranuDrum), tattarawar motsin motsi (kayan GranuPack) da halayen lantarki (kayan aikin GranuCharge).Haɗin kai da ma'aunin motsin motsi suna samuwa don adadin foda masu zuwa.

Foda da ke yadawa cikin sauƙi za su fuskanci ƙananan haɗin kai, yayin da foda tare da saurin cikawa da sauri za su samar da sassa na inji tare da ƙananan porosity idan aka kwatanta da samfurori da ke da wuyar cikawa.

Uku aluminum gami foda (AlSi10Mg) adana a cikin dakin gwaje-gwaje na da dama watanni, tare da daban-daban barbashi size rarraba, da kuma daya 316L bakin karfe samfurin, ake magana a kai a matsayin samfurori A, B da C, aka zaba.Halayen samfurori na iya bambanta da wasu.masana'antun.An auna girman rarrabuwar samfurin ta hanyar nazarin diffraction laser/ISO 13320.

Tun da yake suna sarrafa ma'auni na na'ura, dole ne a yi la'akari da kaddarorin foda na farko, kuma idan muka yi la'akari da foda wanda ba a narkewa ba ya zama gurɓatacce kuma ba za a iya sake yin amfani da shi ba, farashin masana'antun ƙari ba zai zama mai arziki kamar yadda muke so ba.Sabili da haka, za a bincika sigogi uku: kwararar foda, tattarawar kinetics da electrostatics.

Yadawa yana da alaƙa da daidaituwa da kuma "lalata" na foda Layer bayan aikin sake dawowa.Wannan yana da mahimmanci sosai saboda filaye masu santsi suna da sauƙin bugawa kuma ana iya bincika su tare da kayan aikin GranuDrum tare da ma'aunin ma'aunin mannewa.

Saboda pores sune maki masu rauni a cikin abu, zasu iya haifar da fashewa.Matsakaicin tattarawa shine ma'auni mai mahimmanci na biyu saboda saurin tattarawa foda yana da ƙarancin ƙarfi.An auna wannan hali tare da GranuPack tare da ƙimar n1/2.

Kasancewar cajin lantarki a cikin foda yana haifar da haɗin kai wanda ke haifar da samuwar agglomerates.GranuCharge yana auna ikon foda don samar da cajin lantarki akan tuntuɓar kayan da aka zaɓa yayin gudana.

Yayin aiki, GranuCharge na iya hasashen lalacewar kwararar ruwa, kamar samuwar Layer a cikin AM.Don haka, ma'aunin da aka samu yana da matukar damuwa ga yanayin ƙwayar hatsi (haɓaka, gurɓatawa da rashin ƙarfi).Za a iya ƙididdige tsufan foda da aka dawo da shi daidai (±0.5 nC).

GranuDrum ya dogara ne akan ƙa'idar ganga mai juyawa kuma hanya ce da aka tsara don auna ƙarfin foda.Silinda a kwance tare da bangon gefen bayyane ya ƙunshi rabin samfurin foda.Drum ɗin yana jujjuya kusurwoyinsa a saurin kusurwa na 2 zuwa 60 rpm, kuma kyamarar CCD tana ɗaukar hotuna (daga hotuna 30 zuwa 100 a tazarar daƙiƙa 1).Ana gano ƙirar iska / foda akan kowane hoto ta amfani da algorithm gano gefen.

Yi ƙididdige matsakaicin matsakaicin matsayi na dubawa da oscillation a kusa da wannan matsakaicin matsayi.Ga kowane saurin juyi, kusurwar kwarara (ko “tsari mai ƙarfi na kwanciyar hankali”) αf ana ƙididdige shi daga madaidaicin madaidaicin wuri, kuma madaidaicin mannewa σf, wanda ke nufin haɗin haɗin kai, ana bincikar shi daga jujjuyawar dubawa.

Matsakaicin magudanar ruwa yana tasiri da sigogi da yawa: gogayya tsakanin barbashi, siffa da haɗin kai (van der Waals, electrostatic da capillary Forces).Ƙaƙƙarfan foda masu haɗaka suna haifar da raguwa na tsaka-tsaki, yayin da ba tare da haɗin kai ba yana haifar da gudana na yau da kullum.Ƙananan dabi'u na kusurwar kwarara αf sun dace da kyawawan kaddarorin kwarara.Ma'anar mannewa mai ƙarfi kusa da sifili yayi daidai da foda mara daidaituwa, sabili da haka, yayin da mannewar foda ya karu, madaidaicin mannewa yana ƙaruwa daidai.

GranuDrum yana ba ku damar auna kusurwar dusar ƙanƙara ta farko da aeration na foda yayin gudana, da kuma auna ma'aunin mannewa σf da kusurwar kwarara αf dangane da saurin juyawa.

Girman girma na GranuPack, yawan taɓawa da ma'aunin rabo na Hausner (wanda kuma ake kira "gwajin taɓawa") sun shahara sosai a cikin halayen foda saboda sauƙi da saurin aunawa.Girman foda da ikon ƙara yawan adadinsa sune mahimman bayanai a lokacin ajiya, sufuri, agglomeration, da dai sauransu. An kwatanta hanyar da aka ba da shawarar a cikin Pharmacopoeia.

Wannan gwaji mai sauƙi yana da manyan lahani guda uku.Ma'auni sun dogara da mai aiki kuma hanyar cikawa tana shafar ƙarar foda na farko.Ma'auni na gani na ƙara zai iya haifar da kurakurai masu tsanani a cikin sakamakon.Saboda sauƙi na gwajin, mun yi watsi da haɓakar haɓakawa tsakanin matakan farko da na ƙarshe.

An yi nazarin halayen foda da aka ciyar a cikin ci gaba da fitarwa ta amfani da kayan aiki na atomatik.Daidai auna ma'aunin Hausner coefficient Hr, ƙimar farko ρ(0) da ƙimar ƙarshe ρ(n) bayan n dannawa.

Yawan famfo yawanci yana daidaitawa a n=500.GranuPack wani ma'auni ne mai sarrafa kansa kuma ci-gaba na ma'aunin taɓawa dangane da sabon bincike mai ƙarfi.

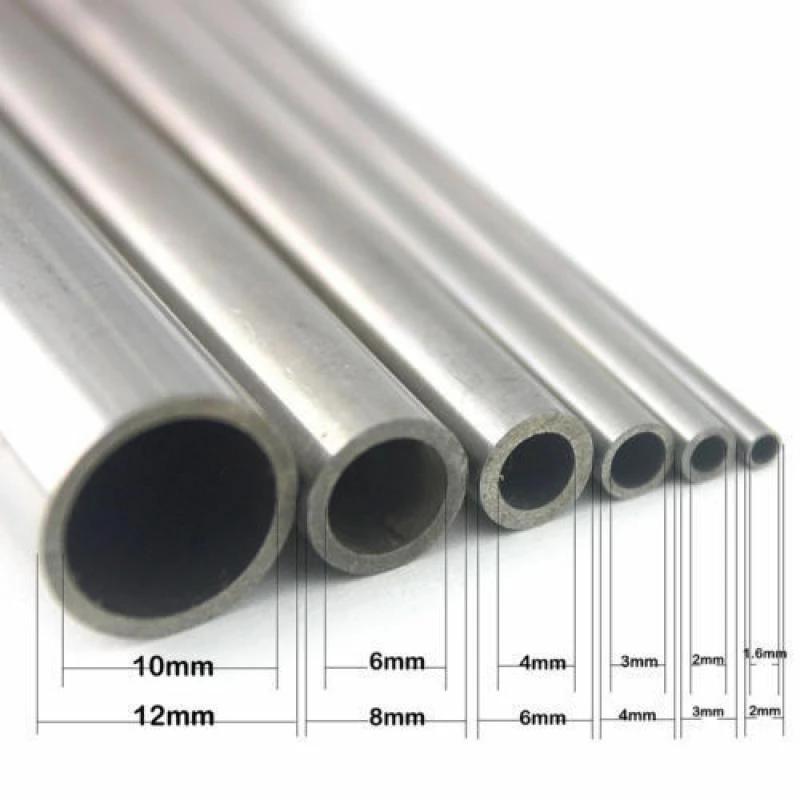

Ana iya amfani da wasu fihirisa, amma ba a jera su anan ba.Ana sanya foda a cikin bututun ƙarfe kuma yana tafiya ta tsarin farawa ta atomatik.Ana ɗaukar madaidaicin siga mai ƙarfi n1/2 da matsakaicin girman ρ(∞) daga madaidaicin madaidaicin.

Silinda mara nauyi mai nauyi yana zaune a saman gadon foda don kiyaye matakin mu'amalar foda/ iska yayin dannewa.Bututu dauke da samfurin foda ya tashi zuwa tsayi mai tsayi ∆Z sannan ya fadi da yardar kaina zuwa tsayi, yawanci ana gyarawa a ∆Z = 1 mm ko ∆Z = 3 mm, auna ta atomatik bayan kowane tasiri.Ta tsayi, zaku iya ƙididdige ƙarar V na tari.

Dnsity shine rabo na taro m zuwa ƙarar V na foda.An san ƙwayar foda m, yawancin ρ ana amfani da shi bayan kowace saki.

Hausner coefficient Hr yana da alaƙa da ƙayyadaddun ƙima kuma ana nazarin shi ta hanyar ƙididdiga Hr = ρ (500) / ρ (0), inda ρ (0) shine farkon girma mai yawa kuma ρ (500) shine ƙididdige yawan adadin famfo bayan 500. famfo.Ana iya sake haifar da sakamakon tare da ƙaramin foda (yawanci 35 ml) ta amfani da hanyar GranuPack.

Abubuwan da ke cikin foda da yanayin kayan da aka yi na'urar sune mahimman sigogi.A lokacin kwarara, ana haifar da cajin electrostatic a cikin foda, kuma waɗannan cajin suna haifar da tasirin triboelectric, musayar caji lokacin da daskararru biyu suka shiga cikin hulɗa.

Lokacin da foda ke gudana a cikin na'urar, tasirin triboelectric yana faruwa a lamba tsakanin barbashi da a lamba tsakanin barbashi da na'urar.

Bayan tuntuɓar kayan da aka zaɓa, GranuCharge ta atomatik yana auna adadin cajin lantarki da aka haifar a cikin foda yayin gudana.Samfurin foda yana gudana a cikin bututun V mai girgiza kuma ya faɗi cikin kofin Faraday da aka haɗa da na'urar lantarki wanda ke auna cajin foda yayin da yake motsawa ta cikin V-tube.Don sakamako mai iya sakewa, ciyar da V-tube akai-akai tare da na'urar juyawa ko girgiza.

Tasirin triboelectric yana sa wani abu ya sami electrons akan samansa kuma ta haka ana cajin shi mara kyau, yayin da wani abu ya rasa electrons don haka ana cajin gaske.Wasu kayan suna samun electrons cikin sauƙi fiye da wasu, hakazalika, sauran kayan suna rasa electrons cikin sauƙi.

Wani abu ya zama mara kyau kuma wanda ya zama tabbatacce ya dogara ne akan yanayin dangi na kayan da ke da hannu don samun ko rasa electrons.Don wakiltar waɗannan halaye, an haɓaka jerin triboelectric da aka nuna a cikin Table 1.An jera kayan da aka saba caje su da kyau da sauran waɗanda aka saba caje su, yayin da aka jera abubuwan da ba su nuna ɗabi'a a tsakiyar tebur ba.

A gefe guda, wannan tebur yana ba da bayanai kawai game da yanayin halin cajin kayan, don haka an ƙirƙiri GranuCharge don samar da ingantattun dabi'u don halayen cajin foda.

An gudanar da gwaje-gwaje da yawa don nazarin bazuwar zafi.An bar samfurori a 200 ° C na sa'o'i daya zuwa biyu.Ana bincika foda nan da nan tare da GranuDrum (sunan thermal).Ana sanya foda a cikin akwati har sai ya kai zafin yanayi sannan a bincika ta amfani da GranuDrum, GranuPack da GranuCharge (watau "sanyi").

An yi nazarin samfurorin danye ta amfani da GranuPack, GranuDrum da GranuCharge a yanayin zafi iri ɗaya/ɗaki, watau dangi zafi 35.0 ± 1.5% da zazzabi 21.0 ± 1.0 °C.

Ƙididdigar haɗin kai yana ƙididdige ƙimar foda kuma yana daidaitawa tare da canje-canje a cikin matsayi na dubawa (foda / iska), wanda ke nuna kawai ƙungiyoyin hulɗa guda uku (van der Waals, capillary da electrostatic).Kafin gwajin, yi rikodin yanayin zafi (RH,%) da zafin jiki (°C).Sa'an nan kuma zuba foda a cikin kwandon ganga kuma fara gwaji.

Mun yanke shawarar cewa waɗannan samfuran ba su da kula da caking yayin la'akari da sigogin thixotropic.Abin sha'awa shine, damuwa na thermal ya canza halayen rheological na foda na samfurori A da B daga girma mai girma zuwa raguwa mai laushi.A gefe guda kuma, Samfurori C da SS 316L ba su shafi yanayin zafi ba kuma sun nuna kauri kawai.Kowane foda ya nuna mafi kyawun yaduwa (watau ƙananan haɗin kai) bayan dumama da sanyaya.

Har ila yau, tasirin zafin jiki ya dogara da takamaiman yanki na barbashi.Mafi girman ma'auni na thermal conductivity na kayan, mafi girman tasiri akan zafin jiki (watau ???225°?=250??-1.?-1) da ?316?225°?=19?Yin aiki a yanayin zafi mai tsayi shine zaɓi mai kyau don foda na aluminum gami saboda haɓakar haɓakar su, kuma samfuran sanyaya sun sami madaidaicin kwararar ruwa idan aka kwatanta da foda na pristine.

Ga kowane gwaji na GranuPack, an rubuta nauyin foda kafin kowane gwaji, kuma samfurin ya kasance mai tasiri na 500 tare da tasirin tasiri na 1 Hz tare da faɗuwar kyauta na tantanin halitta na 1 mm (tasirin makamashi ∝).Ana rarraba samfurori a cikin sel masu aunawa bisa ga umarnin software mai zaman kansa na mai amfani.Sannan an sake maimaita ma'aunin sau biyu don tantance sake fasalin da kuma bincika ma'ana da daidaitaccen karkata.

Bayan an kammala nazarin GranuPack, ƙaddamarwa na farko (ρ (0)), ƙarancin tattarawa na ƙarshe (akan dannawa da yawa, n = 500, watau ρ (500)), Hausner rabo / Carr index (Hr / Cr) , da biyu da aka rubuta sigogi (n1/2 da τ) masu alaƙa da haɓakar haɓakawa.Hakanan ana nuna mafi kyawun ƙimar ρ(∞) (duba Shafi 1).Teburin da ke ƙasa yana sake tsara bayanan gwaji.

Hoto na 6 da 7 suna nuna jimlar tatsuniyoyi (yawan yawa tare da adadin tasirin) da ma'aunin siga n1/2/Hausner.Ana nuna sandunan kurakuran da aka ƙididdige su ta amfani da matsakaita akan kowane lanƙwasa, kuma an ƙididdige madaidaitan sabawa daga gwaje-gwajen maimaitawa.

Samfurin bakin karfe na 316L shine samfurin mafi nauyi (ρ(0) = 4.554 g/mL).Dangane da yawan taɓawa, SS 316L har yanzu shine foda mafi nauyi (ρ (n) = 5.044 g/mL), sannan Samfura A (ρ (n) = 1.668 g/mL), sannan Sample B (ρ (n) ya biyo baya. = 1.668 g/ml) (n) = 1.645 g/ml).Samfurin C shine mafi ƙanƙanta (ρ(n) = 1.581 g/mL).Dangane da girman girman foda na farko, mun ga cewa samfurin A shine mafi sauƙi, kuma la'akari da kuskuren (1.380 g / ml), samfuran B da C suna da kusan ƙimar ɗaya.

Lokacin da foda ya yi zafi, rabonsa na Hausner yana raguwa, wanda ke faruwa kawai don samfurori B, C da SS 316L.Don Samfura A, ba za a iya yin wannan ba saboda girman sandunan kuskure.Don n1/2, yanayin siga ya fi wahalar ganowa.Don samfurin A da SS 316L, ƙimar n1 / 2 ya ragu bayan 2 h a 200 ° C, yayin da foda B da C ya karu bayan hawan thermal.

Anyi amfani da feeder mai girgiza don kowane gwajin GranuCharge (duba Hoto 8).Yi amfani da bututu bakin karfe 316L.An maimaita ma'auni sau 3 don tantance sake haifuwa.Nauyin samfurin da aka yi amfani da shi don kowane ma'auni ya kusan 40 ml kuma ba a dawo da foda ba bayan an auna.

Kafin gwajin, ana yin rikodin nauyin foda (mp, g), yanayin zafi na dangi (RH,%), da zafin jiki (°C).A farkon gwajin, auna yawan cajin foda na farko (q0 a cikin µC/kg) ta hanyar gabatar da foda a cikin kofin Faraday.A ƙarshe, yi rikodin adadin foda kuma ƙididdige ƙimar cajin ƙarshe (qf, µC/kg) da Δq (Δq = qf - q0) a ƙarshen gwajin.

Ana nuna raw bayanan GranuCharge a cikin Table 2 da Hoto 9 (σ shine daidaitattun ƙididdiga da aka lasafta daga sakamakon gwajin sake sakewa), kuma an gabatar da sakamakon a matsayin histograms (q0 da Δq kawai aka nuna).SS 316L yana da mafi ƙarancin farashi na farko;wannan na iya zama saboda gaskiyar cewa wannan samfurin yana da mafi girman PSD.Game da adadin cajin farko na foda na alloy na aluminum na farko, ba za a iya yanke shawara ba saboda girman kurakurai.

Bayan lamba tare da 316L bakin karfe bututu, samfurin A samu a kalla adadin cajin idan aka kwatanta da powders B da C, wanda Highlights irin wannan Trend, a lokacin da SS 316L foda aka rubbed tare da SS 316L, wani cajin yawa kusa da 0 da aka samu (duba triboelectric). jerin).Samfurin B har yanzu yana da caji fiye da A. Don samfurin C, yanayin yana ci gaba (tabbatacciyar cajin farko da cajin ƙarshe bayan yayyo), amma adadin cajin yana ƙaruwa bayan lalatawar thermal.

Bayan sa'o'i 2 na damuwa na thermal a 200 ° C, halin foda ya zama mai ban mamaki.A cikin samfuran A da B, cajin farko yana raguwa kuma cajin ƙarshe yana canzawa daga mara kyau zuwa tabbatacce.SS 316L foda yana da mafi girman cajin farko kuma canjin ƙimarsa ya zama tabbatacce amma ya kasance ƙasa (watau 0.033 nC/g).

Mun bincika tasirin lalatawar thermal akan halayen haɗin gwiwar aluminum gami (AlSi10Mg) da 316L bakin karfe foda yayin nazarin foda na asali a cikin iska na yanayi bayan sa'o'i 2 a 200 ° C.

Yin amfani da foda a babban zafin jiki na iya inganta yaduwar samfurin, kuma wannan tasirin yana da alama ya fi mahimmanci ga foda tare da babban yanki na musamman da kayan aiki tare da haɓakaccen zafi.An yi amfani da GranuDrum don kimanta kwararar ruwa, an yi amfani da GranuPack don bincike mai ƙarfi mai ƙarfi, kuma an yi amfani da GranuCharge don nazarin triboelectricity na foda a cikin hulɗa da 316L bakin karfe tubing.

An kafa waɗannan sakamakon ta amfani da GranuPack, wanda ke nuna haɓakawa a cikin haɗin gwiwar Hausner ga kowane foda (ban da samfurin A saboda kuskuren girman) bayan tsarin damuwa na thermal.Duban sigogin tattarawa (n1/2), babu bayyanannun yanayi kamar yadda wasu samfuran ke nuna haɓakar saurin tattarawa yayin da wasu ke da tasirin bambanta (misali Samfuran B da C).

Lokacin aikawa: Janairu-10-2023