Factors iyakance yanayin aiki

Aikace-aikace na yau da kullun waɗanda ke buƙatar kayan duplex don fallasa zuwa yanayin zafi mai zafi sune tasoshin matsa lamba, ruwan fanfo/masu turawa ko gogewar iskar gas.Abubuwan da ake buƙata don kayan kaddarorin na iya zuwa daga babban ƙarfin injina zuwa juriya na lalata.An jera sinadarai na maki da aka tattauna a cikin wannan labarin a cikin Tebur 1.

Bazuwar spinodal

Bazuwar spinodal (wanda kuma ake kira demixing ko kuma a tarihi kamar 475 ° C-embrittlement) wani nau'in rabuwa ne na lokaci a cikin lokacin zafi, wanda ke faruwa a yanayin zafi kusan 475 ° C.Mafi mahimmancin sakamako shine canji a cikin microstructure, yana haifar da samuwar α' lokaci, wanda ya haifar da ƙaddamar da kayan aiki.Wannan, bi da bi, yana iyakance aikin samfurin ƙarshe.

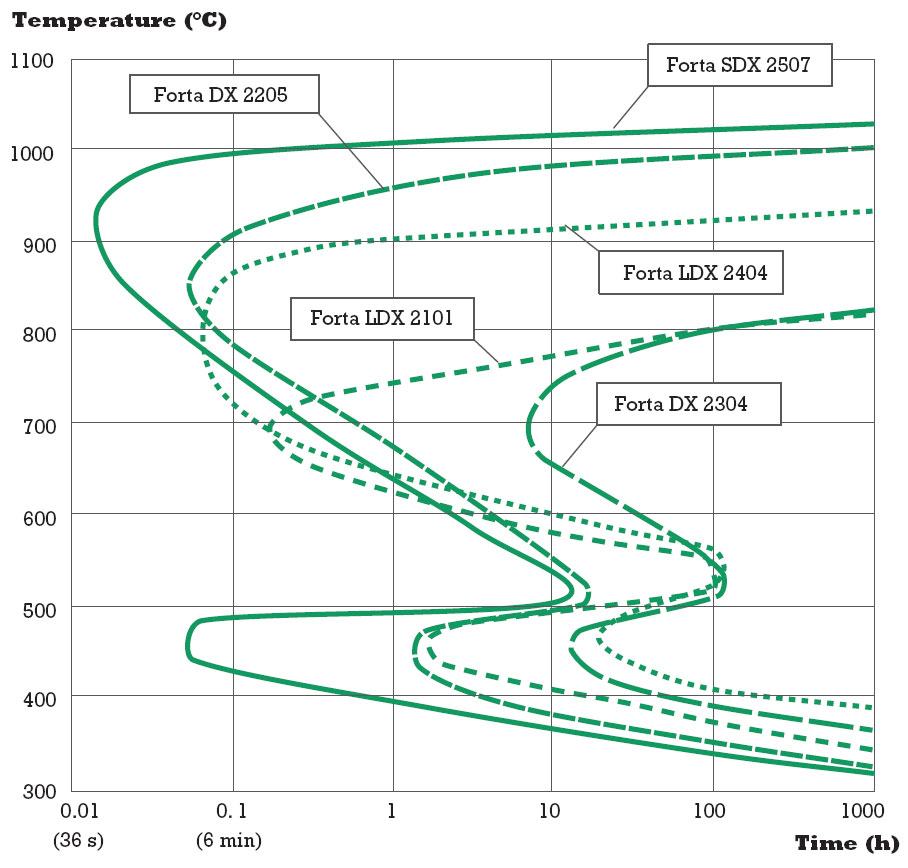

Hoto na 1 yana nuna zane-zanen lokacin canjin zafin jiki (TTT) don kayan aikin duplex da aka yi nazari, tare da bazuwar spinodal da aka wakilta a cikin yanki na 475 °C.Ya kamata a lura cewa wannan zane na TTT yana wakiltar raguwar tauri da kashi 50% wanda aka auna ta gwajin ƙarfin ƙarfi akan samfuran Charpy-V, wanda yawanci ana karɓa azaman yana nuna ɓarna.A wasu aikace-aikace za a iya yarda da raguwar ƙarfin ƙarfi, wanda ke canza siffar zanen TTT.Don haka, yanke shawarar saita takamaiman OT na musamman ya dogara da abin da ake ɗauka a matsayin matakin karɓuwa na haɓakawa watau rage ƙarfi ga samfurin ƙarshe.Ya kamata a ambata cewa an kuma samar da jadawali na tarihi ta hanyar amfani da ƙofa da aka saita, kamar 27J.

Maɗaukakin alloyed maki

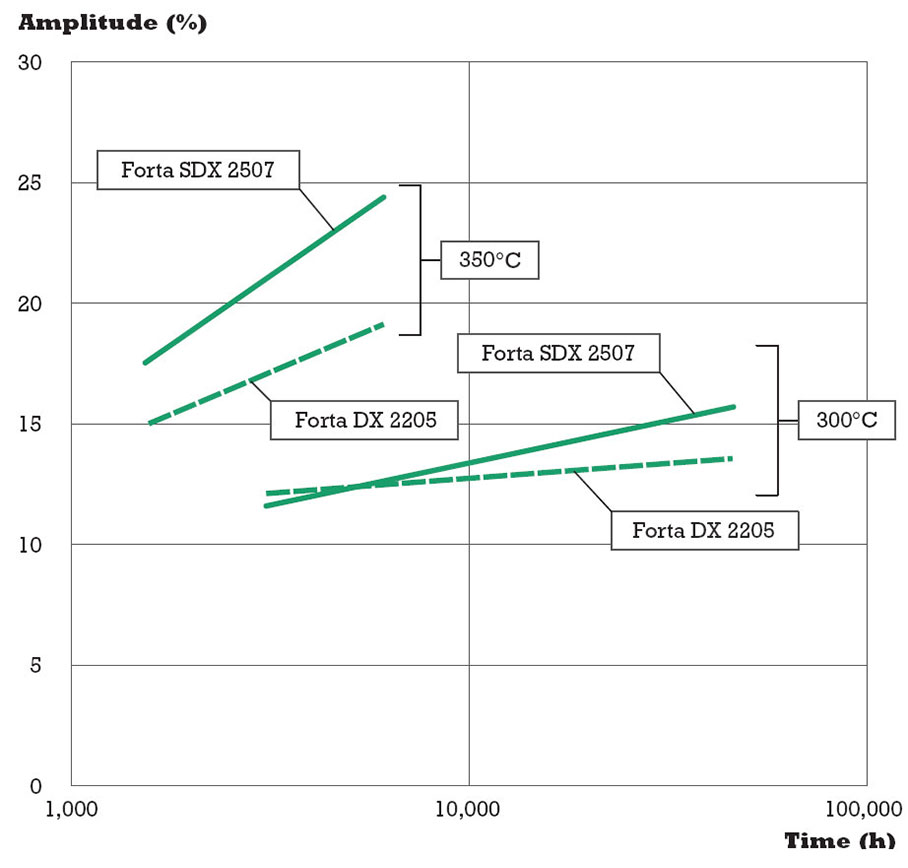

Hoto na 1 ya nuna cewa haɓakar abubuwan haɗaɗɗun abubuwa daga sa LDX 2101 zuwa matakin SDX 2507 yana haifar da saurin ruɓewa, yayin da duplex duplex yana nuna jinkirin farkon bazuwar.An nuna tasirin abubuwan da ke haɗa abubuwa kamar chromium (Cr) da nickel (Ni) a kan lalatawar spinodal da embrittlement ta hanyar binciken da suka gabata. An haɓaka daga 300 zuwa 350 °C kuma ya fi sauri don mafi girman alloyed sa SDX 2507 fiye da ƙarancin alloed DX 2205.

Wannan fahimtar na iya zama mahimmanci don taimakawa abokan ciniki su yanke shawara akan iyakar OT wanda ya dace da zaɓaɓɓen maki da aikace-aikacen su.

Ƙayyade matsakaicin zafin jiki

Kamar yadda aka ambata a baya, ana iya saita matsakaicin OT don kayan duplex bisa ga faɗuwar ƙimar tasiri.Yawanci, OT wanda yayi daidai da ƙimar rage taurin kashi 50% ana karɓa.

OT ya dogara da yanayi & lokaci

Matsakaici a cikin wutsiyoyi na masu lanƙwasa a cikin zane na TTT a hoto na 1 yana nuna cewa bazuwar spinodal ba ya faruwa ne kawai a yanayin zafi ɗaya kuma ya tsaya ƙasa da wannan matakin.Maimakon haka, tsari ne na dindindin lokacin da kayan duplex suka fallasa yanayin yanayin aiki a ƙasa da 475 ° C.Ko da yake kuma a bayyane yake cewa, saboda ƙananan ƙimar yaduwa, ƙananan yanayin zafi yana nufin bazuwar zai fara daga baya kuma ya ci gaba a hankali.Don haka, yin amfani da kayan duplex a ƙananan zafin jiki bazai haifar da matsaloli na shekaru ko ma shekaru da yawa ba.Amma duk da haka a halin yanzu akwai hali don saita iyakar OT ba tare da la'akari da lokacin fallasa ba.Tambaya mai mahimmanci shine don haka menene haɗin lokacin zafin jiki ya kamata a yi amfani da shi don yanke shawara ko yana da aminci don amfani da kayan ko a'a?Herzman et al.10 sun taƙaita wannan matsala da kyau: "...Amfani da za a iyakance ga yanayin zafi inda motsin demixing ya yi ƙasa da cewa ba zai faru ba a lokacin da aka tsara rayuwar fasaha na samfurin...".

Tasirin walda

Yawancin aikace-aikacen suna amfani da walda don haɗa abubuwan haɗin gwiwa.Sanannen abu ne cewa microstructure na weld da sunadarai sun bambanta daga kayan tushe 3.Dangane da kayan filler, dabarar walda da sigogin walda, ƙananan ƙirar walda sun bambanta da babban kayan.Microstructure yawanci yana da ƙarfi, kuma wannan kuma ya haɗa da yankin da ya shafa zafi mai zafi (HTHAZ), wanda ke yin tasiri ga bazuwar spinodal a cikin walda.Bambancin ƙananan tsarin tsakanin girma da walƙiya jigo ne da aka sake dubawa anan.

Takaitawa abubuwan iyakancewa

Sassan da suka gabata suna haifar da sakamako masu zuwa:

- Duk kayan duplex abin magana ne

zuwa bazuwar spinodal a yanayin zafi kusan 475 ° C. - Dangane da abun ciki na alloying, ana sa ran saurin lalacewa ko a hankali.Babban abun ciki na Cr da Ni yana haɓaka haɓakawa cikin sauri.

- Don saita iyakar zafin aiki:

- Dole ne a yi la'akari da haɗuwa da lokacin aiki da zafin jiki.

– Matsayin da aka yarda da shi na raguwa a cikin tauri, watau, matakin da ake so na taurin ƙarshe dole ne a saita - Lokacin da aka gabatar da ƙarin abubuwan haɗin microstructural, irin su walda, matsakaicin OT yana ƙayyade mafi rauni.

Matsayin duniya

An sake duba ƙa'idodin Turai da Amurka da yawa don wannan aikin.Sun mayar da hankali kan aikace-aikace a cikin tasoshin matsin lamba da abubuwan bututun.Gabaɗaya, bambance-bambancen game da iyakar shawarar OT a tsakanin ƙa'idodin da aka sake dubawa za a iya raba su zuwa mahangar Turai da Amurka.

Matsayin ƙayyadaddun ƙayyadaddun kayan Turai don bakin karfe (misali EN 10028-7, EN 10217-7) yana nuna matsakaicin OT na 250 ° C ta gaskiyar cewa kayan kayan ana ba da su har zuwa wannan zafin jiki.Hakanan, ƙa'idodin ƙirar Turai don tasoshin matsa lamba da bututu (EN 13445 da EN 13480 bi da bi) ba su ba da ƙarin bayani game da matsakaicin OT daga abin da aka bayar a cikin ka'idodin kayan su.

Sabanin haka, ƙayyadaddun kayan Amurka (misali ASME SA-240 na sashin ASME II-A) baya gabatar da duk wani bayanan zafin jiki ko kaɗan.Ana ba da wannan bayanan a maimakon ASME sashe II-D, 'Properties', wanda ke goyan bayan ƙa'idodin gini na gabaɗaya don tasoshin matsa lamba, ASME sashe VIII-1 da VIII-2 (ƙarshen yana ba da hanyar ƙira mafi ci gaba).A cikin ASME II-D, matsakaicin OT an bayyana shi a sarari azaman 316 ° C don yawancin gami da duplex.

Don aikace-aikacen bututun matsa lamba, ana ba da dokokin ƙira da kaddarorin kayan a cikin ASME B31.3.A cikin wannan lambar, an ba da bayanan injina don allo na duplex har zuwa 316 ° C ba tare da bayyananniyar madaidaicin OT ba.Duk da haka, zaku iya fassara bayanin don biyan abin da aka rubuta a cikin ASME II-D, don haka, matsakaicin OT na ƙa'idodin Amurka shine 316 ° C.

Baya ga mafi girman bayanin OT, duka ƙa'idodin Amurka da na Turai suna nuna akwai haɗarin haɗuwa da ɓarna a yanayin zafi mai tsayi (>250 ° C) a mafi tsayin lokacin bayyanarwa, wanda sannan yakamata a yi la'akari da shi a cikin ƙira da lokacin sabis.

Ga welds, yawancin ma'auni ba sa yin wani tabbataccen magana kan tasirin bazuwar spinodal.Koyaya, wasu ƙa'idodi (misali ASME VIII-1, Teburin UHA 32-4) suna nuna yuwuwar yin takamaiman jiyya na zafi bayan walda.Ba a buƙatar waɗannan kuma ba a haramta su ba, amma lokacin yin su ya kamata a aiwatar da su bisa ga sigogin da aka riga aka saita a cikin ma'auni.

Abin da masana'antu ke cewa

An sake duba bayanan da wasu masana'antun bakin karfe da yawa suka samar don ganin abin da suke sadarwa game da kewayon zafin makinsu.2205 yana iyakance a 315 ° C ta ATI, amma Acerinox ya saita OT don maki ɗaya a 250 ° C kawai.Waɗannan su ne ƙayyadaddun OT na sama da na ƙasa don digiri na 2205, yayin da a tsakanin su sauran OTs ana sadarwa ta Aperam (300 ° C), Sandvik (280°C) da ArcelorMittal (280 ° C).Wannan yana nuna yaɗuwar matsakaicin matsakaicin OTs kawai don aji ɗaya waɗanda zasu mallaki kaddarorin kwatankwacinsu daga masana'anta zuwa masana'anta.

Ba koyaushe yana bayyana dalilin da yasa masana'anta ya saita takamaiman OT ba.A mafi yawan lokuta, wannan yana dogara ne akan ƙayyadaddun ƙa'idodi ɗaya.Ma'auni daban-daban suna sadarwa daban-daban OTs, saboda haka yaduwa cikin ƙima.Ƙarshe mai ma'ana ita ce kamfanonin Amurka sun kafa ƙima mafi girma saboda maganganun da ke cikin ma'auni na ASME, yayin da kamfanonin Turai suka kafa ƙananan ƙima saboda ma'auni na EN.

Menene abokan ciniki ke bukata?

Dangane da aikace-aikacen ƙarshe, ana sa ran nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan abubuwan.A cikin wannan aikin, ɓarna saboda bazuwar spinodal shine mafi yawan sha'awa saboda yana da amfani sosai ga tasoshin matsa lamba.

Koyaya, akwai aikace-aikace daban-daban waɗanda ke fallasa maki duplex zuwa matsakaicin nauyi na inji kawai, kamar su goge11-15.Wata buƙatun kuma tana da alaƙa da ruwan fanfo da abubuwan motsa jiki, waɗanda ke fuskantar lodin gajiya.Littattafai sun nuna cewa bazuwar spinodal yana nuna hali daban-daban lokacin da aka yi amfani da nauyin gajiya15.A wannan mataki, ya bayyana a fili cewa matsakaicin OT na waɗannan aikace-aikacen ba za a iya saita shi daidai da tasoshin matsa lamba ba.

Wani nau'in buƙatun shine don aikace-aikacen da ke da alaƙa da lalata kawai, kamar masu goge iskar gas na ruwa.A cikin waɗannan lokuta, juriya na lalata ya fi mahimmanci fiye da iyakancewar OT a ƙarƙashin nauyin inji.Koyaya, abubuwan biyu suna tasiri aikin samfurin ƙarshe, wanda dole ne a yi la'akari da shi lokacin nuna matsakaicin OT.Har ila yau, wannan shari'ar ta bambanta da shari'o'i biyu da suka gabata.

Gabaɗaya, lokacin ba da shawara ga abokin ciniki mafi girman madaidaicin OT don maki duplex ɗin su, nau'in aikace-aikacen yana da mahimmanci a saita ƙimar.Wannan yana ƙara nuna rikitarwa na saita OT guda ɗaya don matsayi, kamar yadda yanayin da ake amfani da kayan yana da tasiri mai mahimmanci akan tsarin ƙaddamarwa.

Menene iyakar zafin aiki don duplex?

Kamar yadda aka ambata, matsakaicin zafin jiki na aiki an saita shi ta ƙananan motsin motsa jiki na bazuwar spinodal.Amma ta yaya za mu auna wannan zafin jiki kuma menene ainihin "low kinetics"?Amsar tambaya ta farko tana da sauƙi.Mun riga mun bayyana cewa ana yin ma'aunin tauri don ƙididdige ƙima da ci gaban lalacewa.An saita wannan a cikin ƙa'idodin da yawancin masana'antun ke bi.

Tambaya ta biyu, a kan abin da ake nufi da ƙananan motsin motsa jiki da kuma darajar da muke saita iyakar zafin jiki ya fi rikitarwa.Wannan wani bangare ne tun lokacin da yanayin iyakar iyakar zafin jiki an haɗa shi daga duka madaidaicin zafin jiki (T) kansa da lokacin aiki (t) wanda wannan zafin ya dore.Don tabbatar da wannan haɗin Tt, ana iya amfani da fassarori daban-daban na taurin "ƙananan":

• Ƙarƙashin iyaka, wanda aka saita a tarihi kuma ana iya amfani da shi don walda shine 27 Joules (J)

• A cikin ma'auni galibi an saita 40J azaman iyaka.

Ana amfani da raguwar 50% a farkon taurin farko don saita ƙananan iyaka.

Wannan yana nufin cewa sanarwa akan iyakar OT dole ne ta kasance bisa aƙalla zato guda uku da aka amince da su:

• Bayyanar lokacin zafin samfurin ƙarshe

• Mafi ƙarancin ƙima na tauri

• Filin aikace-aikace na ƙarshe (sunadarai kawai, nauyin injin eh/a'a da sauransu)

Haɗaɗɗen ilimin gwaji

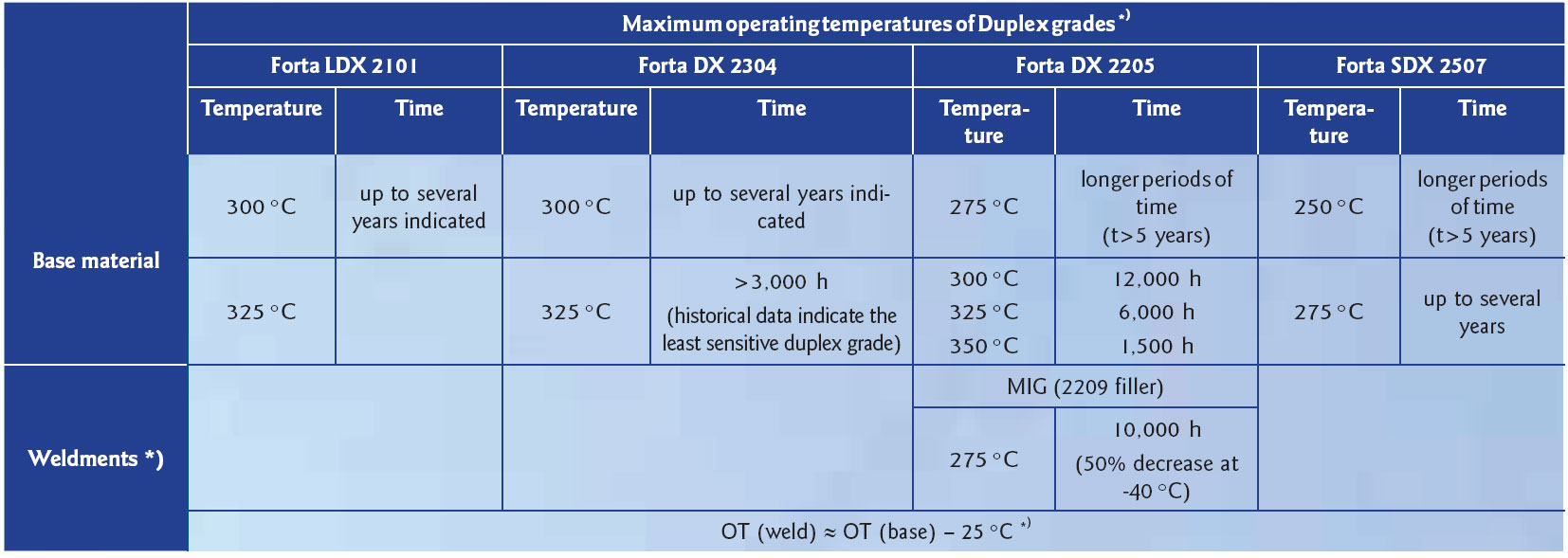

Bayan bincike mai zurfi game da bayanan gwaji da ka'idoji ya yiwu a tattara shawarwari don maki huɗu na duplex da ake dubawa, duba Table 3. Ya kamata a gane cewa yawancin bayanan an halicce su ne daga gwaje-gwajen dakin gwaje-gwaje da aka yi tare da matakan zafin jiki na 25 ° C. .

Hakanan ya kamata a lura cewa waɗannan shawarwarin suna yin la'akari da aƙalla 50% na ƙarfin da ya rage a RT.Lokacin da aka nuna "tsawon lokaci" a cikin tebur babu wani raguwa mai mahimmanci a cikin RT da aka rubuta.Bugu da ƙari, an gwada walda kawai a -40 ° C.A ƙarshe, ya kamata a lura cewa ana tsammanin tsawon lokacin bayyanarwa don DX 2304, la'akari da tsananin ƙarfinsa bayan awoyi 3,000 na gwaji.Duk da haka, har zuwa irin yadda za a iya ƙara bayyanarwa dole ne a tabbatar da ƙarin gwaji.

Akwai muhimman abubuwa guda uku da ya kamata a lura da su:

Binciken na yanzu yana nuna cewa idan akwai waldi, OT yana raguwa da kusan 25 ° C.

• Ƙimar gajeren lokaci (dubun sa'o'i a T=375 °C) ana karɓa don DX 2205. Kamar yadda DX 2304 da LDX 2101 sun kasance ƙananan ma'auni na allo, kwatankwacin ƙananan zafin jiki na gajeren lokaci ya kamata a karɓa.

• Lokacin da aka ƙaddamar da abu saboda bazuwar, ƙaddamar da maganin zafi a 550 - 600 ° C don DX 2205 da 500 ° C don SDX 2507 don 1 hour yana taimakawa wajen dawo da taurin ta 70%.

Lokacin aikawa: Fabrairu-04-2023