Alloy 625 Bakin Karfe Coil Tubing Farashin

Haɗin Sinadari, %

Alloy 625 abu ba maganadisu bane, austenitic, kuma yana nuna ƙarfin ƙarfi mai ƙarfi, ƙirƙira, da brazeability.Saboda yawan abun ciki na nickel, wannan gami yana da kusan rigakafi ga chloride ion stress-corrosion cracking and pitting, wanda galibi ana samun shi a cikin karafa a aikace-aikacen ruwan teku kamar masu musayar zafi, manne, da sheathing na USB.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Rago | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S |

| 5.0 max | .50 max | .50 max | .015 max | .015 max |

A waɗanne aikace-aikace ake amfani da Inconel 625?

- Inconel 625 ana amfani da shi a masana'antar Aerospace

- Tsarin bututun jirgi

- Tsarin injin jet

- Injin tura-reverser tsarin

- Kayan aikin ruwan teku na musamman

- Chemical tsarin kayan aiki

Bayanin ASTM

| Pipe Smls | Bututu Weld | Tube Sml | Tube Weld | Shet/Plate | Bar | Ƙirƙira | Daidaitawa | Waya |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Kayayyakin Injini

| Temp°F | Tensile (psi) | .2% Yawan Haihuwa (psi) | Tsawaitawa cikin 2" (%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel 625 Melting Point

| Matsayin narkewa | 1290-1350 °C | 2350 - 2460 °F |

Inconel 625 Daidai

| STANDARD | Ayyukan Aiki NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Farashin 625 | 2.4856 | N06625 | Farashin 625 | NA 21 | ХН75МБТЮ | Saukewa: NC22DNB4MNiCr22Mo9Nb | NiCr23F |

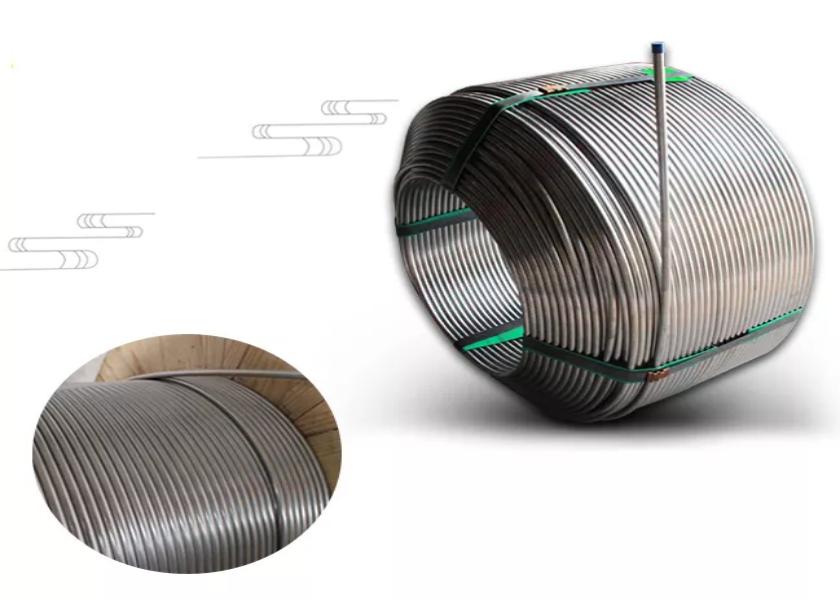

Alloy 625 Tubing

Alloy 625 shine austenitic nickel-chromium-molybdenum superalloy wanda aka sani da kasancewa mai jurewa lalata lalata da iskar oxygen a yanayin zafi mai tsayi.Waɗannan yanayin zafi na iya kewayo daga cryogenic zuwa matakan zafi na 1,800F.Halaye da sinadarai na wannan matakin sun sa ya dace da aikace-aikacen nukiliya da sararin samaniya.Hakanan, tare da ƙari na niobium, gami da tubing 625 sun sami kanta tare da ƙarin ƙarfi ba tare da jin zafi ba.Wannan kadarar ta sa darajar ta zama kyakkyawan zaɓi don ƙirƙira.

Ƙayyadaddun samfur

ASTM B444 / ASME SB444 / NACE MR0175

Girman Rage

| Wajen Diamita (OD) | Kaurin bango |

| .375-.750" | .035-095" |

Abubuwan Bukatun Sinadarai

Alloy 625 (UNS N06625)

Abun ciki %

| C Carbon | Mn Manganese | Si Siliki | P Phosphorous | Cr Chromium | Nb+Ta Niobium-Tantalum | Co Cobalt | Mo Molybdenum | Fe Iron | Al Aluminum | Ti Titanium | Ni Nickel |

| 0.10 max | 0.50 max | 0.50 max | 0.015 max | 20.0-23.0 | 3.15–4.15 | 1.0 max | 8.0-10.0 | 5.0 max | 0.40 max | 0.40 max | 58.0 min |

Hakuri Mai Girma

| OD | Haƙuri OD | Haƙurin bango |

| .375"-0.500" ban da | +.004”/-.000” | ± 10% |

| 0.500"-1.250" ban da | +.005"/-.000" | ± 10% |

Kayayyakin Injini

| Ƙarfin Haɓaka: | 60 ksi min |

| Ƙarfin Ƙarfafawa: | 120 ksi min |

| Tsawaitawa (minti 2): | 30% |

Hotunan Factory

Dubawa

Shipping & Packing

Rahoton Gwaji