Galo 600 Bakin Karfe Coil Tubing Farashin

Haɗin Sinadari, %

Aikace-aikacen lalata na yau da kullun sun haɗa da samar da titanium dioxide (hanyar chloride), ƙirar perchlorethylene, vinyl chloride monomer (VCM), da magnesium chloride.Ana amfani da Alloy 600 a cikin sinadarai da masana'antar abinci da adanawa, maganin zafi, phenol condensers, kera sabulu, kayan lambu da tasoshin fatty acid da ƙari mai yawa.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 min | 14.0-17.0 | 6.0-10.0 | .15 max | 1.00 max | .015 max | .50 max | .50 max |

A waɗanne aikace-aikace ake amfani da Inconel 600?

- Masana'antar sinadarai

- Jirgin sama

- Masana'antar maganin zafi

- Pulp da takarda masana'antu

- sarrafa abinci

- Injiniyan Nukiliya

- Abubuwan injin turbin gas

Bayanin ASTM

| Pipe Smls | Bututu Weld | Tube Sml | Tube Weld | Shet/Plate | Bar | Ƙirƙira | Daidaitawa | Waya |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Kayayyakin Injini

Yawan zafin jiki na ɗaki na ɗaki na kayan da aka rufe

| Samfurin Samfura | Yanayi | Tensile (ksi) | .2% Haihuwa (ksi) | Tsawaitawa (%) | Hardness (HRB) |

| Rod & Bar | Sanyi-Jawo | 80-100 | 25-50 | 35-55 | 65-85 |

| Rod & Bar | Zafi-Gama | 80-100 | 30-50 | 35-55 | 65-85 |

| Tube & Bututu | Zafi-Gama | 75-100 | 25-50 | 35*55 | - |

| Tube & Bututu | Sanyi-Jawo | 80-100 | 25-50 | 35-55 | 88 Max |

| Plate | Zafi-Rolled | 80-105 | 30-50 | 35-55 | 65-85 |

| Shet | Sanyi-Jawo | 80-100 | 30-45 | 35-55 | 88 Max |

Inconel 600 Melting Point

| Abun ciki | Yawan yawa | Matsayin narkewa | Ƙarfin Ƙarfin Ƙarfi | Ƙarfin Haɓaka (0.2% Kashe) | Tsawaitawa |

| Alloy 600 | 8.47 g/cm 3 | 1413 °C (2580 °F) | Psi - 95,000, MPa - 655 | Psi - 45,000, MPa - 310 | 40% |

Inconel 600 Daidai

| STANDARD | Ayyukan Aiki NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Alloy 600 | 2.4816 | N06600 | Farashin NCF600 | NA 13 | МНЖМц 28-2,5-1,5 | Saukewa: NC15FE11M | NiCr15F |

Alloy 600 Tubing

Alloy 600 shine kyakkyawan ɗan takara don amfani da yawa a cikin matsanancin zafin jiki da yanayin lalata sosai.Haɗin nickel da chromium yana haifar da tsayayyen juriya ga iskar shaka a yanayin zafi mai aiki.Waɗannan yanayin zafi na iya kewayo daga cryogenic zuwa matakan zafi na 2,000F.Babban abun ciki na nickel na gami 400 kuma yana ba da juriya ta kusan-cikakke ga lalatawar damuwa, wanda galibi ana samunsa a cikin mahallin chloride.

Yana da mahimmanci a lura cewa ɓangaren chromium na bayanan sinadarai na gami yana ba da damar ƙimar darajar jure yanayin zafi.Mafi kyawun tsarin hatsi na bututun da aka gama sanyi, bugu da ƙari, yana kawo mafi kyawun juriya na lalata, wanda ya haɗa da gajiya mai girma da ƙimar ƙarfin tasiri.

Ƙayyadaddun samfur

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Girman Rage

| Wajen Diamita (OD) | Kaurin bango |

| .250-.750" | .035-083" |

Abubuwan Bukatun Sinadarai

Alloy 600 (UNS N06600)

Abun ciki %

| Ni Nickel | Cu Copper | Fe Iron | Mn Manganese | C Carbon | Si Siliki | S Sulfur | Cr Chromium |

| 72.0 min | 0.50 max | 6.00-10.00 | 1.00 max | 0.15 max | 0.50 max | 0.015 max | 14.0-17.0 |

Hakuri Mai Girma

| OD | Haƙuri OD | Haƙurin bango |

| ≤.500” ban da | +.005” | ± 12.5% |

| .500"-.750" ban da | +.005” | ± 12.5% |

Kayayyakin Injini

| Ƙarfin Haɓaka: | 35 ksi min |

| Ƙarfin Ƙarfafawa: | 80 ksi min |

| Tsawaitawa (minti 2): | 30% |

Kera

Alloy 600 za a iya sauƙi welded ta misali tsari.Gudanar da wannan gami yana da kyau kwarai, yana zama tsakanin mai amfani na T303 da T304.

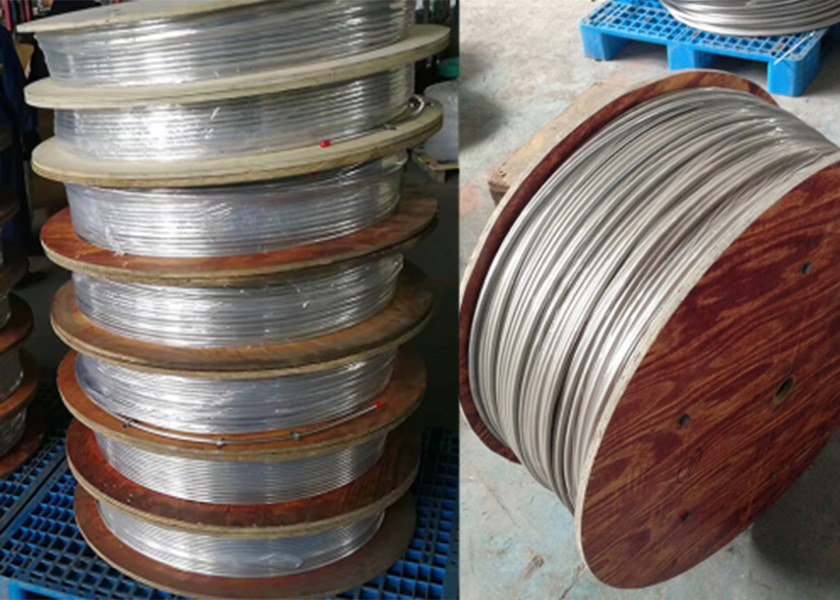

Hotunan Factory

Dubawa

Shipping & Packing

Rahoton Gwaji