3003 aluminum na'ura mai kauri tube

Menene Ma'anar 3003 A Aluminum Coil?

Lambobin da ke cikin coil aluminum sune lambar allo, wanda ke gaya muku abubuwan da ke cikin gami.Lamba na farko yana nufin mafi mahimmancin abin da ya haɗa shi.Lamba na biyu yana nuna bambancin alloy (idan ya bambanta da sifili), kuma lamba ta uku da ta huɗu tana gano jerin sa.

Domin 3003 aluminum coil, lambar farko '3' na nufin shi alloy ne a cikin jerin manganese, '0' yana nufin ba shi da bambanci, kuma lambobi na ƙarshe '03' yana nufin daga jerin 3000.Wannan tsarin ƙididdigewa ya dogara ne akan Tsarin Ƙirar Aloy na Ƙasashen Duniya.

Properties Na 3003 Alloy Aluminum Coil

3003 aluminum coil yana da iyakar abun da ke ciki na siliki 0.6, 0.7 baƙin ƙarfe, 0.05-0.20 jan karfe, 1-1.5 manganese, 0.10 zinc, da 0.15 daga wasu abubuwa.

Aluminum 3003 yana da ƙarfi mai ƙarfi har zuwa 200MPa, kuma duk hanyoyin suna iya walda shi da sauri.Yana da juriya ga lalata a mafi yawan mahalli sai dai lokacin da aka fallasa shi ga ruwan teku ko wasu gurɓatattun yanayi masu ɗauke da chlorine ko fluorine.

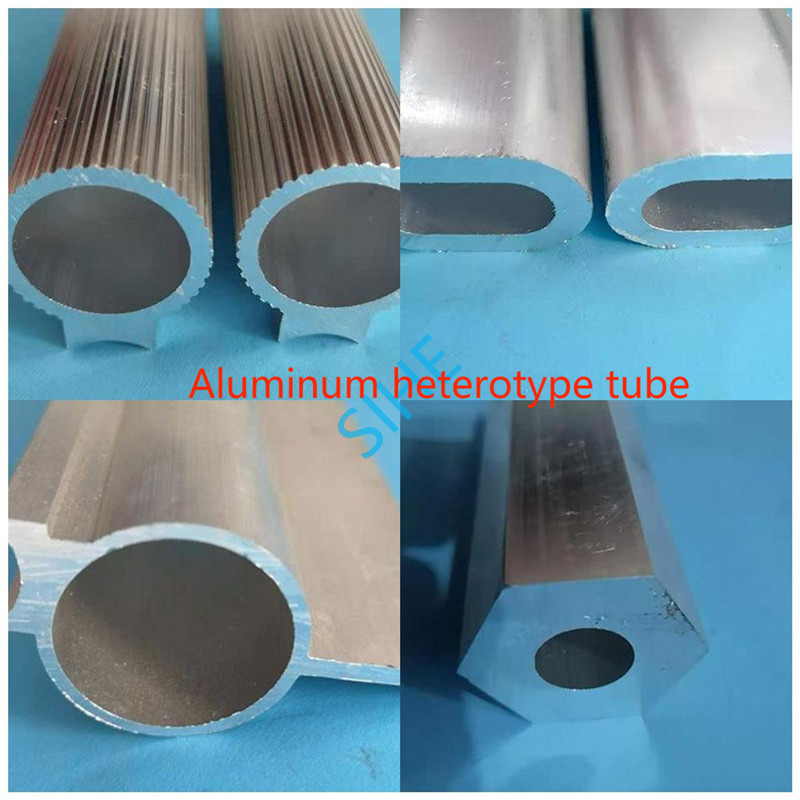

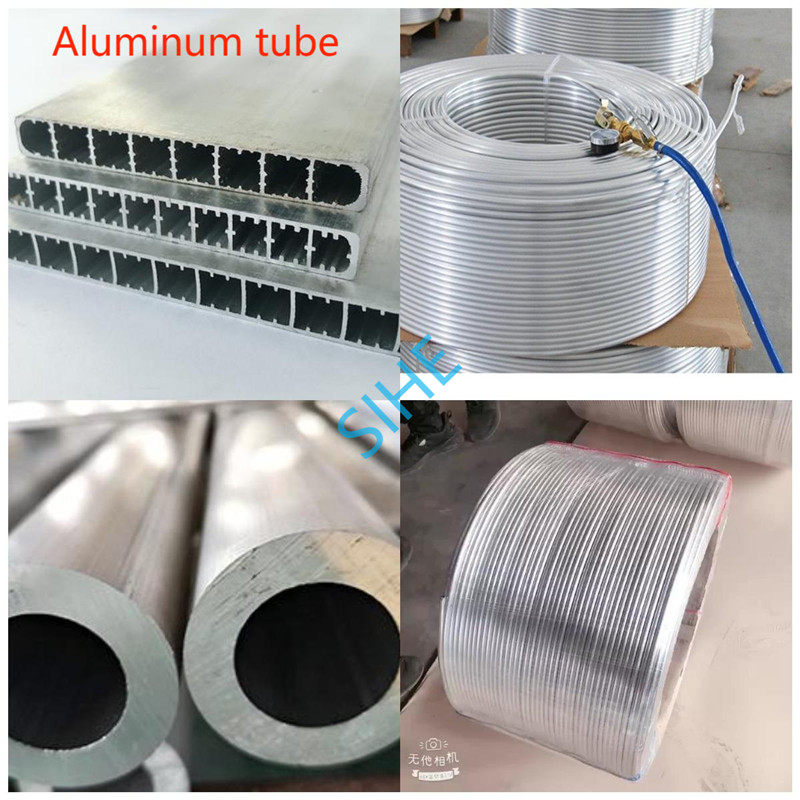

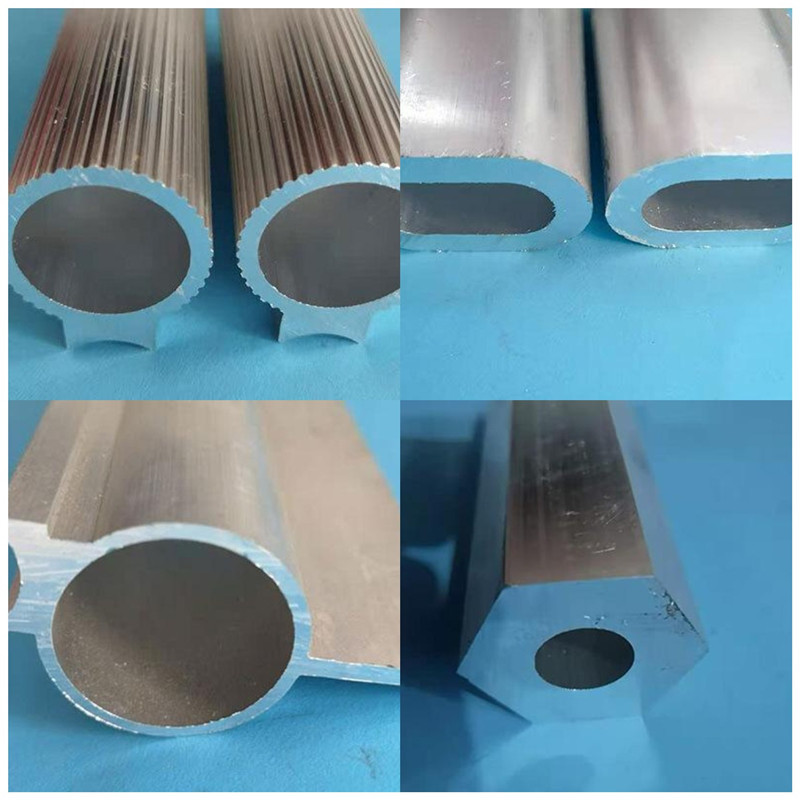

3003 alloy aluminum coils zo a cikin daban-daban siffofi da kuma girma dabam - jere daga zanen gado kawai 0.4 mm kauri zuwa 12 mm kauri tubes.Akwai zaɓuɓɓuka da yawa lokacin yanke shawarar kayan kowane aikin.Hakanan ana samun su a cikin coils (don amfanin masana'antu) da tsayin tsayi (don ayyukan kasuwanci).

3003 Aluminum Coil Vs.3004 Aluminum Coil

3003 aluminum coil da 3004 aluminum coil ana amfani da su a cikin aikace-aikace masu yawa.Duk da yake suna da kamanceceniya, ba iri ɗaya ba ne, kuma kowanne yana da fa'ida da illa.

Alloys 3003 da 3004 suna kama da juna a cikin abun da ke ciki, amma 3004 yana da ƙarin 1% magnesium, yana sa ya ɗan ƙara ƙarfi.Wannan yana haifar da mafi kyawun juriya na lalata lokacin da aka fallasa shi zuwa yanayin acid, yana sa wannan gami ya fi tsada don samarwa fiye da 3003 gami.

3003 aluminum gami yana ba da mafi kyawun ductility fiye da 3004 gami da weldability saboda ƙananan abun ciki na magnesium;duk da haka, yana da ƙarancin ƙarfi-zuwa-nauyi fiye da kayan na ƙarshe saboda ƙananan ƙarancinsa.

Game da aikace-aikacen muhalli, 3003 za a iya magance zafi da aiki sanyi, amma 3004 za a iya yin aikin sanyi kawai.

Ƙayyadaddun bayanai

| Alloy A'a. | Haushi | Madaidaicin Tube | LWC | ||

| OD (mm) | WT (mm) | OD (mm) | WT | ||

| 1060 (L2) | R (H112) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| M (O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H 14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 3A21 3003 3103 (LF21) | M (O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 |

| H12 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H14 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| H18 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.2 ~ 2 | |

| 6063 (LD31) | M (O) | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 |

| T4 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

| T6 | 6 ~ 30 | 0.6 ~ 3 | 4 ~ 22 | 0.5 ~ 2 | |

Ƙayyadaddun Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwa na Ciki na Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwar Ƙaƙwalwa )

| Ƙayyadaddun (mm) | Kaurin bango (mm) | Tsawon Tsayi (mm) | Hannun Hannu (°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Kayayyakin Injini Na Ciki Aluminum Grooed Tube

| Kayan abu | Tashin hankali | Yawan Tsawaitawa | Fadada Ƙimar |

| 3003 | 130MPA | 35 | 40 |

Ƙayyadaddun Fakitin Coil

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Kaurin bango | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

Garanti mai yawa

| A1050 Aluminum Chemical Haɗin | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Wasu |

| 99.5-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.40 | 0 ~ 0.03 |

| A1060 Aluminum Chemical Haɗin | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Wasu |

| 99.6-100 | 0 ~ 0.25 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.03 | 0 ~ 0.03 | / | 0 ~ 0.35 | |

| A1070 Aluminum Chemical Haɗin gwiwa | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Wasu |

| 99.7-100 | 0 ~ 0.2 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.04 | 0 ~ 0.03 | 0 ~ 0.03 | 0 ~ 0.05 | 0 ~ 0.25 | |

| A3003 Aluminum Chemical Haɗin Kai | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Wasu Single | |

| wasu | 0 ~ 0.6 | 0.05 ~ 0.20 | 0 ~ 0.1 | 1.0 ~ 1.5 | 0 ~ 0.70 | 0 ~ 0.05 | |

| Alloy | Haushi | Ƙayyadaddun bayanai | |||

| Kauri (mm) | Diamita (mm) | Ƙarfin ƙarfi | Tauri | ||

| 7075 7005 (tube) | T5,T6,T9 | > 0.5 | 5.0-80 | > 310 Mpa | >140 |

| 6061 6063 (bayanin martaba) | T5,T6 | > 1.6 | 10-180 | > 572 Mpa | HB90-110 |

| Tsawon: <6Mita | |||||

| FUSHI | KAuri (mm) | KARFIN TSINCI | LONGATION% | Daidaitawa |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

Aluminum samfurin